Universal next generation exterior and interior cladding panel

Magnesium sulfate panel with fiber reinforcement

The best alternative to gypsum, calcium silicate, fiber cement, magnesium oxide or cement construction panels

Fire resistant

In the fire resistance rating according to standard EN 13501-1, MUXBOARD panel meets class A1 with fire resistance of 2 and 3 hours, corresponding to EI 120 min and EI 180 min (EN 13501-2).

Water resistant

The panel has special dimensional stability and does not swell even in areas with high humidity levels, such as bathrooms. Even exposure to water or moisture does not cause physical changes in the panel properties. It forms a high moisture barrier and has very high resistance to thermal movements during hot and cold cycles (thermal shock resistance).

Lightweight

The panel weighs only 950 kg/m3, but at the same time is very resistant to bending loads, and its light weight helps save time and therefore costs during construction. It is easy to prepare and attach. The panel can be easily cut using stationary or manual saws. The panel can be nailed without causing deformation or cracking. Its surface is suitable for both textured and smooth plaster application, and can be painted, wallpapered, tiled, etc.

Sound insulating

Foam particles provide excellent sound insulation for walls, floors and ceilings.

Very durable

A wall made from Muxboard panel is extremely stable and very impact resistant. A 6 mm thick Muxboard panel is more durable than a 9.5 mm thick gypsum-based drywall panel. An 8 mm thick Muxboard panel can even replace a 12.5 mm thick gypsum board.

Non-toxic

No chloride ions (formaldehyde) or asbestos are used in the production of Muxboard panels, and it is very durable and chemically stable. It is not harmful to people or the environment. Muxboard panel is manufactured without asbestos or other harmful inorganic fibers.

Environmentally friendly

The panel is made from natural inorganic raw materials. Muxboard panel does not contain cellulose and therefore prevents mold fungus growth (unlike paper or wood products).

Comparison with other materials

| Property | MUXBOARD | Gypsum board | MGO | Fiber cement | OSB |

|---|---|---|---|---|---|

| Fire resistance | Excellent | Poor | Excellent | Excellent | Poor |

| Water resistance | Excellent | Poor | Good | Poor | Poor |

| Robustness and service life | Excellent | Poor | Excellent | Excellent | Poor |

| Mold prevention | Excellent | Poor | Excellent | Poor | Poor |

| Cutting / nailing | Excellent | Good | Excellent | Poor | Good |

| Chloride ion content | 0% | 0% | 10% | 0% | 0% |

| Sound insulation and thermal insulation | Excellent | Good | Excellent | Good | Poor |

| Lightweight | Excellent | Good | Good | Poor | Good |

| Recycling | Excellent | Poor | Good | Poor | - |

| Wallpaper use | Excellent | Good | Good | Poor | - |

| Non-toxicity | Excellent | Poor | Good | Good | Poor |

| Insect resistance | Excellent | Poor | Excellent | Poor | Poor |

| Extended product warranty | Yes | No | Yes | No | No |

| Smoke emission | None | Low | None | None | High |

| Flame spread | None | Low | None | None | High |

| Antibacterial properties | Yes | No | Yes | No | No |

Technical specification

| Parameter | Description |

|---|---|

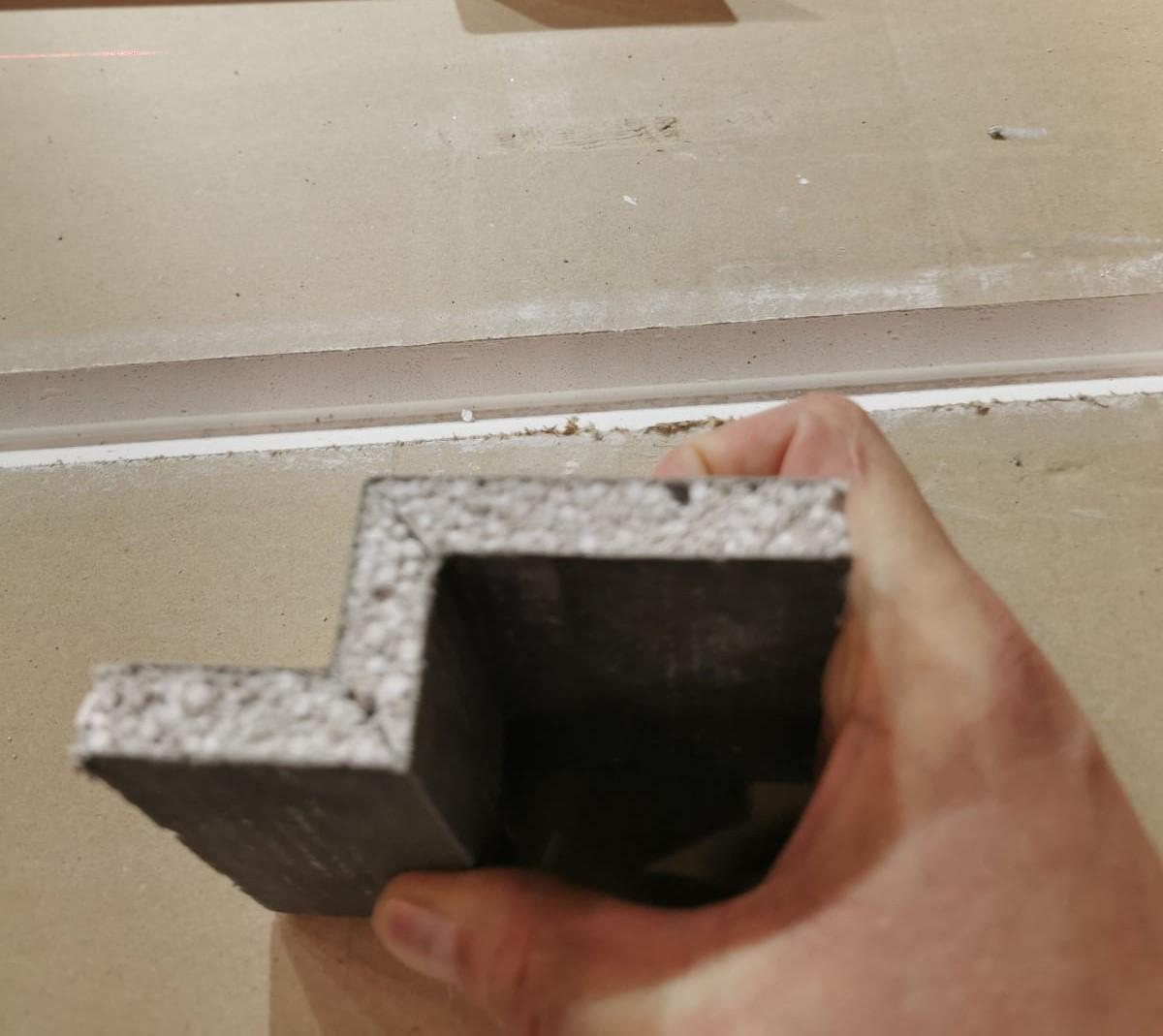

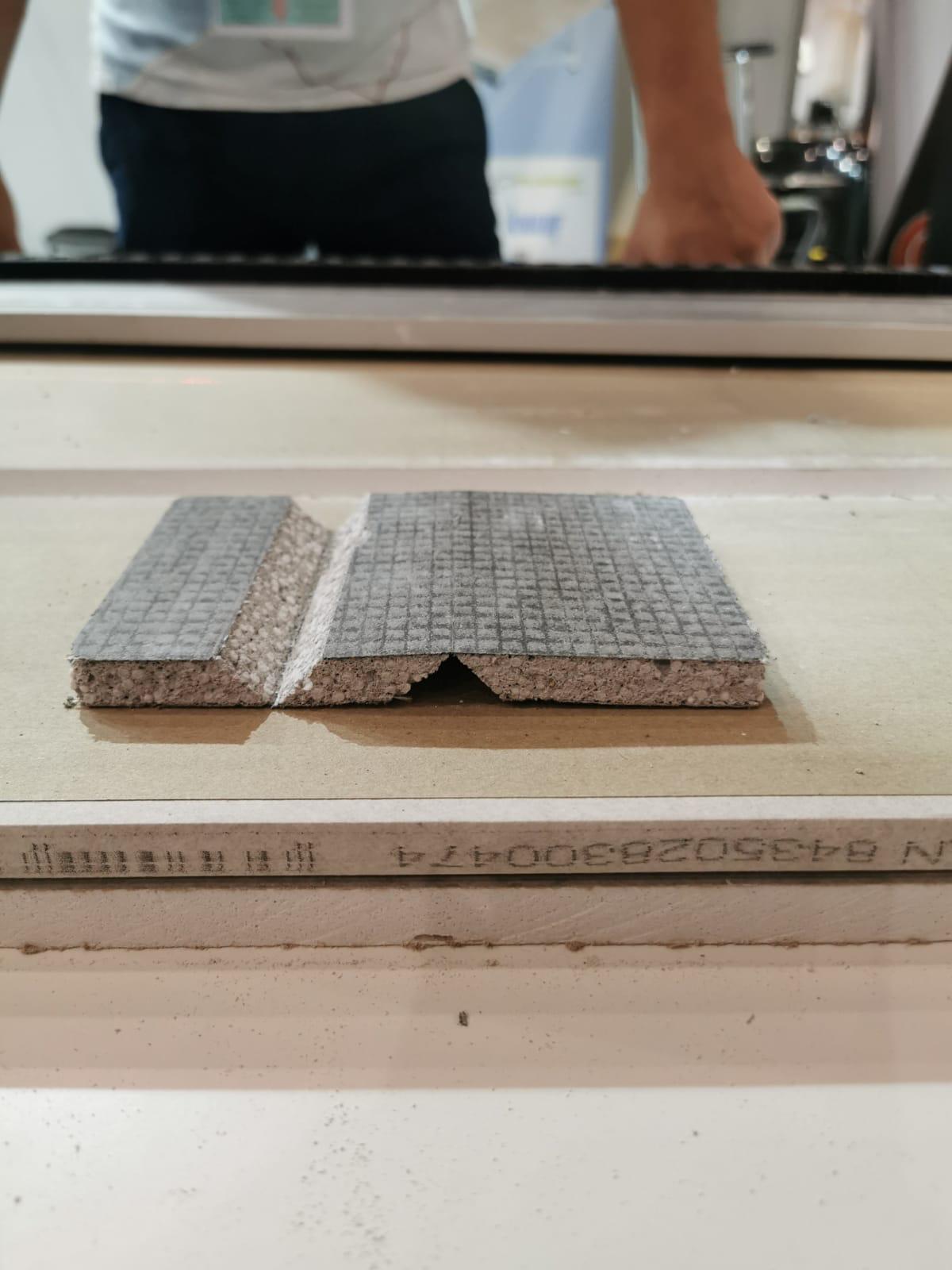

| Raw material | Magnesium sulfate cement, natural plant fiber, fiberglass fabric, foam particles. |

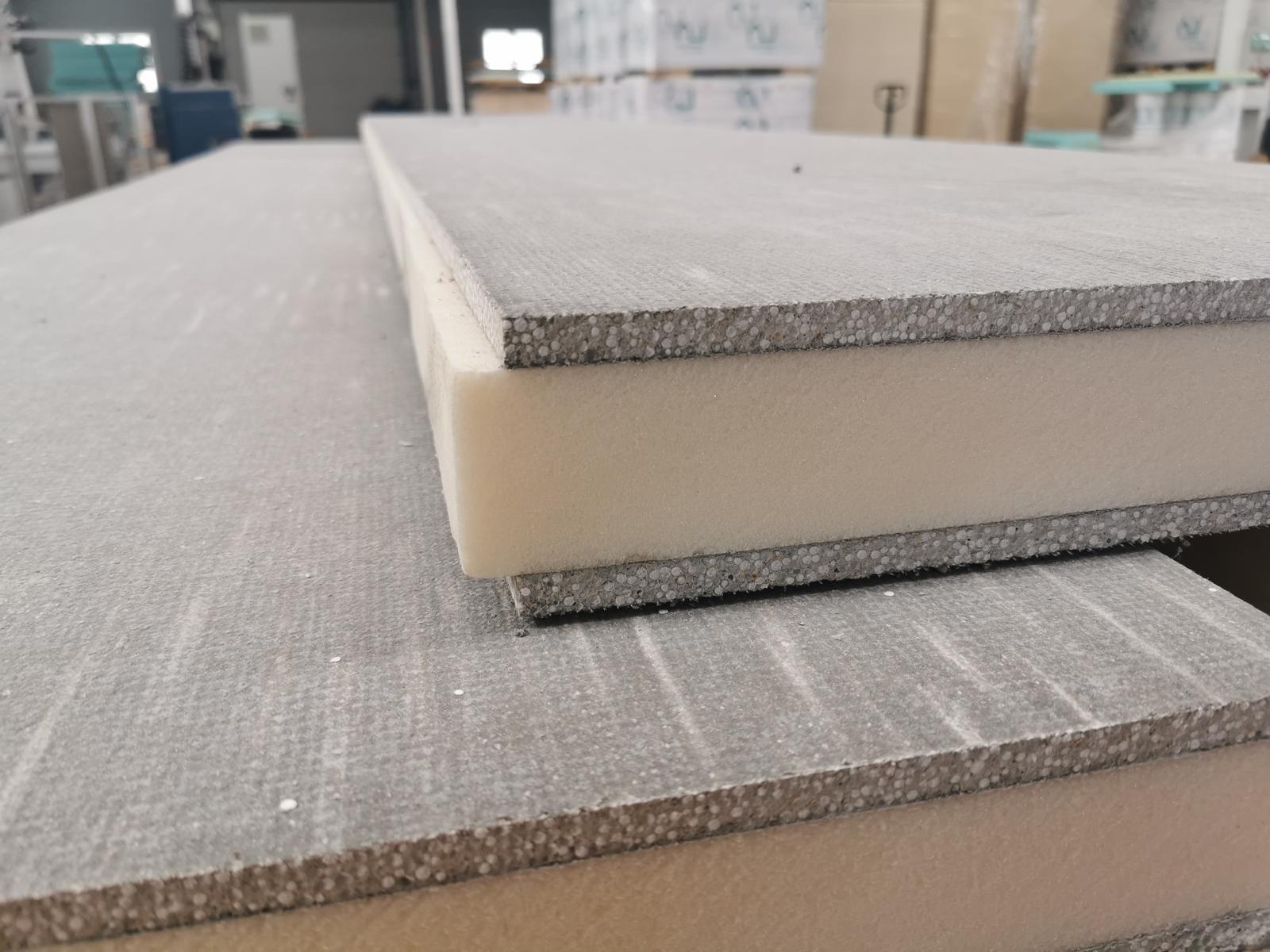

| Dimensions | 1200×2600 mm / 1250×2600 mm (custom sizes available) |

| Thickness | 6, 8, 10, 12, 20 mm (custom sizes available) |

| Water resistant coating | Optional: high quality impregnation liquid (manufacturer Wacker, Germany) |

| Density | < 0.95 g/cm³ |

| Water content | ≥8 % |

| Chloride ion content | 0 % |

| Formaldehyde emission | 0 % |

| Asbestos content | 0 % |

| Fire resistance | Class A1 – non-combustible (EN 13501-1) |

| Fire resistance | EI 120 min and EI 180 min (EN 13501-2/EN 1364-1:2015) |

| Water absorption | ≥23 % |

| Bending strength | >6.5 Mpa |

| Impact resistance | >1.5 KJ/m |

| Nail holding capacity | 16 N/mm |

| Water permeability | No water vapor after 24 hour test |

| Water vapor diffusion coefficient | 54 μ |

| Thermal conductivity | ≤0.2 W/mK |

| Sound insulation | >41 dB |

| Moisture movement | ≥0.12 % |

| Thermal shrinkage | <0.5 |

| Freeze-thaw | No deformation after 100 repeated freeze-thaw cycles |